Diamond Dressing Tools Manufacturing

Since 1841 we have strived to be there for our customers, to respond to their needs, to reduce their costs, and most importantly, to respect them. It is our passionate pursuit of perfection that has enabled us to succeed in becoming the best at what we do. But we will never rest, or be complacent in what we have achieved.

A number of factors enter into the performance of a diamond wheel dresser. Each is important, but particularly with single and multiple point tools, there's nothing more important than the diamond itself. They are the hardest naturally occurring substance. While diamonds consist of pure carbon, their shape and quality can vary enormously, and each variant has it's own effect on tool performance and economy. Among naturally formed diamonds, all but the most expensive, gem quality stones will have flaws. These can be evidenced as slight discolorations, which only rarely affect the performance of the diamond, or they can be seen as cracks and fissures. Whether located near the stone's surface or deep in its core, even the slightest cracks can cause poor performance and premature failure. At Dessau, we use the best quality diamonds and technology in our tools manufacturing process.

We may not know what a diamond dressing tool will look like in another 100 years, but if it is state of the art...it will be DESSAU. Excellence, Integrity... First, Last, Always ...

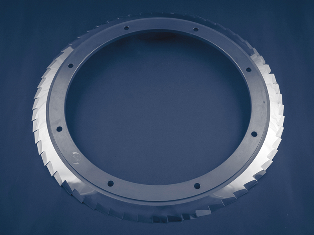

Diamond Dressing Tools and Wheels